XRT

X-Ray Tomography

Characterisation Installation 4

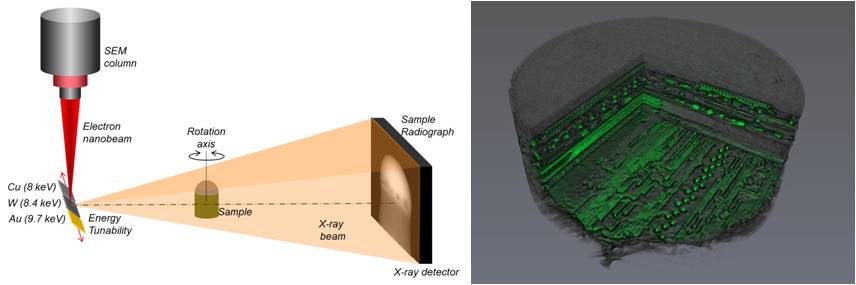

X-ray tomography consists in recording a series of radiographs of a sample at different orientations. The decrease in intensity is characterized by Beer's Law, which describes intensity reduction as a function of X-ray energy, path length, and material linear attenuation coefficient. A specialized algorithm is then used to reconstruct the distribution of X-ray attenuation in the volume being imaged. Typical voxel size depends on source size, detector resolution... and varies from few tens of nm to few µm and beyond. Scanning x-ray tomography can also be performed using an x-ray beam focused on the sample. In that case, 3D imaging is obtained by measuring for each angle of rotation the scattered signal all along a series of linear paths. The signal scattered by the sample can be x-ray fluorescence, x-ray diffraction, x-ray absorption spectroscopy or x-ray excited optical luminescence. Mainly used in synchrotron facilities, the resolution is given by the beam size on the sample. Concerned scientific domains include 3D microelectronics, materials for energy or biology.

Nano-CT

Ag, Mo, W... (high-Z materials)

Nano-wire shaped anodes for high-resolution images, or bulk anodes for higher X-ray flux

Up to 20 keV X-rays (selectable through the use of different anode materials and different e-beam acceleration voltage)

Indirect X-ray detection system. Scientific CMOS from Photonic Science: 45 µm scintillator thickness, CCD composed of 2048x2048 pixels with 11 µm physical pixel size, quantum efficiency ~60% at low spatial frequency, low read noise (~1,8 e- rms)