DXRL

Deep X-Ray Lithography

Lithography & Patterning Installation 1

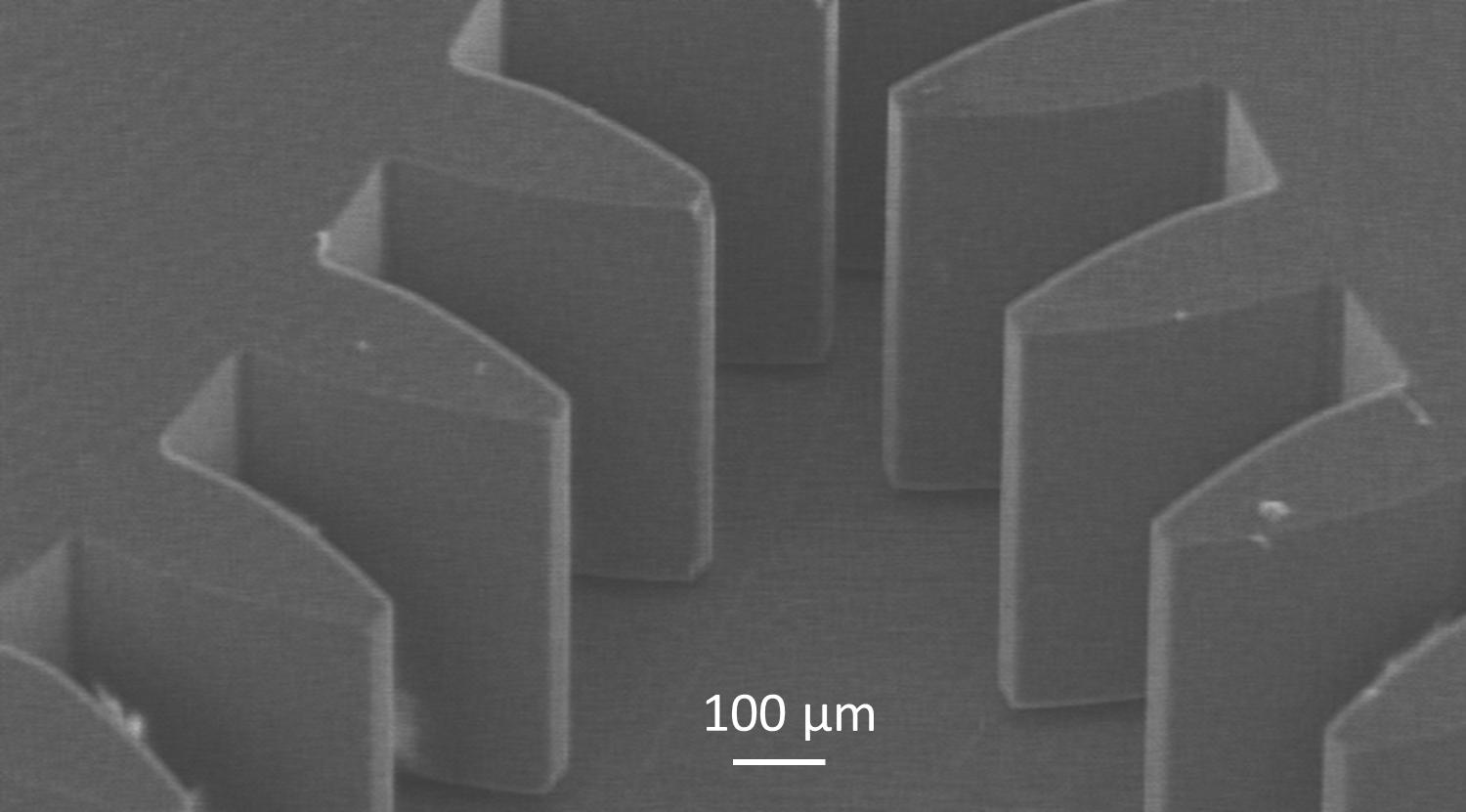

Deep X-Ray Lithography (DXRL) is a manufacturing process by which a material, which changes its dissolution rate in a liquid solvent (developer) under high energy irradiation, is exposed through an X-ray mask to synchrotron radiation. The pattern of the mask is transferred to the material. This is possible by the availability of synchrotron radiation characterized by high brilliance and extreme parallelism. Coupled with electrodeposition, casting, hot embossing, molding, or microelectroerosion (the so called LIGA process), it allows using a wide range of materials: plastics, metals and alloys, ceramics. It is a very flexible tool for fabricating microdevices.

The beamline performs an irradiation of samples with controlled X-ray doses, favouring material science studies and the fabrication of microdevices made of new materials like silica, titania, carbon bucky papers, new TR polymers…

Therefore, DXRL is a key technique to fill the gap between the nano/bio scale (current target of cutting edge studies) and the macroscale, allowing manipulation and analysis of nano-sized objects.

The possibility to fabricate micromolds or microelectrodes for the production of small batches of microdevices, makes LIGA process suitable for industrial applications.

The facility provides access to the Deep X-ray Lithography beamline, equipped with a DEX02 Jenoptik scanner which allows a fully automatic exposure procedure, a scanning speed ranging from 1-50 mm/s, the irradiation of 4 inches masks and resist substrates (water cooled), horizontal and vertical apertures, and an exposure area of 54x84 mm. A set of 5 filters allows a tailored hardening of the beam so obtain a better dose contrast especially for thick resists. The exposures can be performed at 90 mbar in helium or nitrogen atmosphere. Specific sample holders have been designed for powder irradiation and new sample holders can be designed and constructed for particular applications.

A chemical lab with a chemical and a laminar hood, spin and dip-coater, oven (CARBOLITE, which reaches a maximum temperature of 1100 ˚C), balances, stirrers is available.

In order to characterize the structures, the following tools are available:

1- Optical Microscope LEICA MZ125

2- UV-VIS spectrometer (Cary 60, Agilent Technologies) equipped with a standard cuvette holder and a Slide-Mounted External Specular Reflectance. Interchangeable masks for examining small samples or small areas of large samples are provided.

3- FT- IR spectrometer (Alpha-T, Bruker Optics) equipped with modules for the analysis of different types of samples.