FIB

Focused Ion Beam

Lithography & Patterning Installation 1

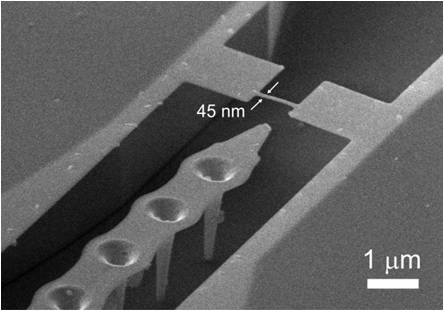

The common FIB Workstation is a high resolution FE-SEM combined with a FIB Ga+ column plus a multi channel gas injection system: Pt, C, W, Co, Au and SiOx are some of the usual precursors for ion or electron induced deposition (FIBID/FEBID); and Fluorine, Iodine or H2O are used for enhanced etching. It can be equipped with different detectors: Everhart-Thornley SE, In-lens SE detector, Backscattered Detector, EDX or STEM among others. Such systems are usually equipped with several nanomanipulators which allow both manipulation and electrical contacting in-situ, and an electron beam-blanker and nanolithography capabilities are also an option.

The main application areas are Nanofabrication and prototyping with nanometric resolution, FIB site specific cross sectioning and SEM inspection on a wide variety of samples (electronics, ceramics, metallurgy, biology…), TEM lamellae preparation, circuit editing and electrical and mechanical inspection in vacuum conditions, nanolithography both with ions or electrons... Actually, due to its high performance and accessories different applications are arising continuously.

WARNING: Access available only to CNR-IOM, but not for TEM sample preparation

LEO-ZEISS Cross-Beam 1540 XB system

FIB - Zeiss 1560XB Cross Beam (N7)

Plasma FIB V-Ion FEI

Strata 400 FEI