UV/EUV-IL

Ultra Violet/Extreme UV - Interference lithography

Lithography & Patterning Installation 1

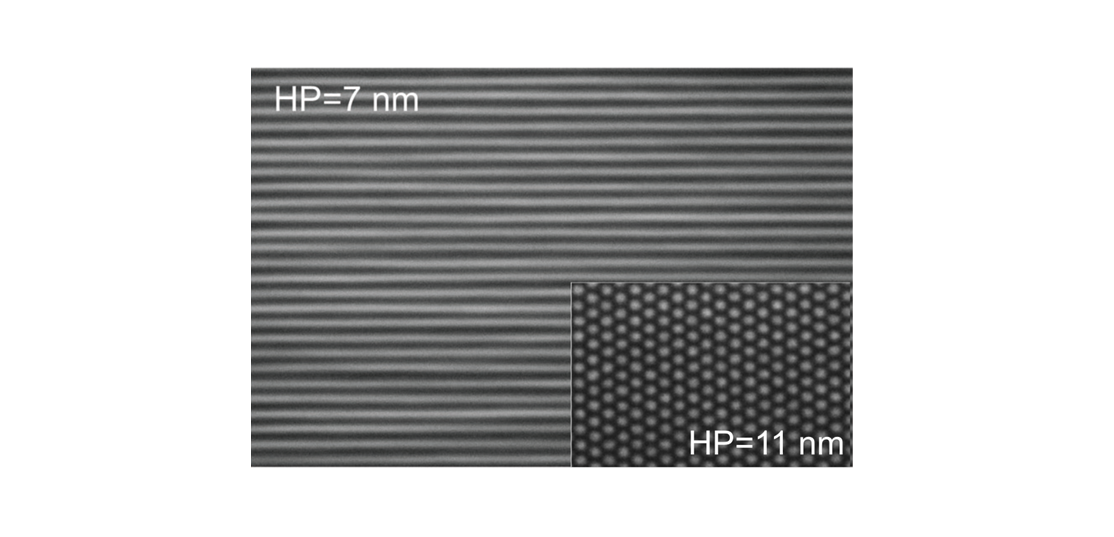

EUV-IL uses a spatially coherent beam from the synchrotron with a variable wavelength from 16 nm down to 3 nm (usually operated at 13.5 wavelength where the synchrotron is capable of providing fully coherent illumination). The beam eventually reaches the mask which comprises two or more diffractive gratings fabricated on a silicon nitride membrane. The beams through these gratings form an interference pattern on a photosensitive material previously spin-coated onto a substrate. The tool can provide extremely high resolution patterning for periodic structures. Unlike electron beam lithography which is a direct write technique, EUV-IL can provide very high throughput and it does not suffer from proximity effects. In addition, it is insensitive to charging and therefore insulating substrates are in principle enabled. One or two dimensional patterns are easily obtained by the use of two or multiple beams respectively. In the simple two-beam case, the fringe period is equal to half of the period of the grating on the mask (for first order diffraction). EUV-IL can have various applications: nanoimprint stamps, fluidic confinement structures, plasmonics and metamaterials, polymer grafting, biomaterials, catalysis, templated assembly, cell growth templates, nanomagnetism, Fresnel zone plates, resist evaluation etc.

EUV-IL - XIL-II Beamline @ Swiss Light Source Synchrotron