Chemical solution deposition

Growth & Synthesis Installation 2

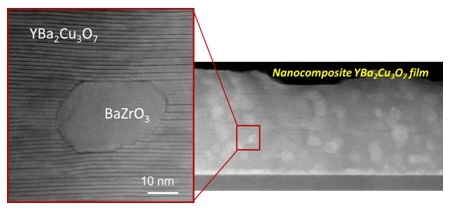

CSD is an ex-situ materials growth technique where chemical solutions are first prepared using inorganic or metalorganic metal salts which are dissolved in either organic or water in stoichiometric ratios to be used as precursors for complex materials. These solutions are then deposited onto a substrate using any of the available methodologies (spin coating, dip coating, web coating, ink jet printing, etc.), depending on the size and characteristics of the desired material to be prepared. The film thickness can be easily controlled through selection of the salts concentration in the solutions and each deposition technique requires specific rheological properties. CSD can also be used to prepare self-assembled nanostructures using ultradiluted solutions while nanocomposite films are prepared, either using complex multicomponent solutions leading to spontaneous phase separation of immiscible crystalline phases, or using colloidal solutions with prepared nanoparticles. Stabilized solutions of nanoparticles can be prepared following different approaches, among them microwave reactors.

The first characteristics which need to be controlled therefore in CSD growth are the chemical purity, metal stoichiometric relationship of the metal ions, the solution stability and rheological properties of the solutions (viscosity, contact angle, surface tension), as well as nanoparticle size and solution stability in the case of colloidal solutions. DLS and TEM are useful tools to characterize the nanoparticle size in the solutions.

After film deposition, the solutions are dried and the chemical precursors pyrolyzed to lead to an amorphous or nanocrystalline porous solid with well-defined thickness. A wide range of thermal processes can be applied for this step, usually performed under well-defined controlled atmospheres and heating ramps. Specific furnaces need to be used and analytical tools allow correlating the decomposition process with the films microstructure. Film thickness can be carefully controlled through selection of solution and depositions parameters and it can be measured through optical interferometry, ellipsometry or profilometry. TGA-DTA, Evolved Gas Analysis (EGA), optical and electron microscopy, IR spectroscopy and X-ray diffraction are the most common tools to follow the film evolution during or after the thermal processes. TEM and cross section FIB images are also very useful to analyze the film homogeneity and final porosity.

The final step to achieve high quality films is a selected high temperature growth process which transforms intermediate phases into the final desired phase. Control of the nucleation and growth conditions will closely determine the final microstructure and functionality of the films. Different types of heating procedures have been used (conventional resistive heating, rapid thermal annealing, laser annealing) to prepare ferromagnetic, ferroelectric, multiferroic, metallic, semiconducting or superconducting materials.