CVD

Chemical Vapour Deposition

Growth & Synthesis Installation 2

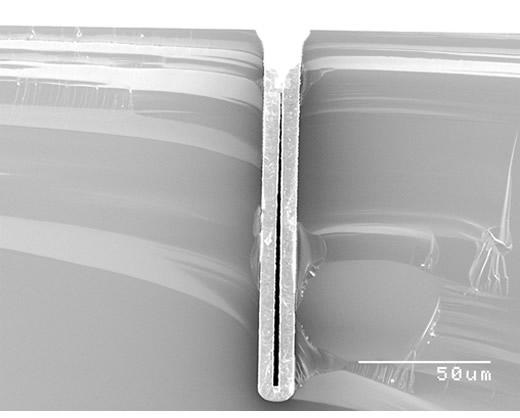

CVD is a thermal process because a certain thermal energy is needed to decompose the gas precursors and reassemble them in the material to be deposited. Processing conditions in a CVD should avoid gas-phase reactions (homogenous deposition) and should favor that the deposited layer is assembled in the substrate as a surface process (heterogeneous deposition). This can be achieved at atmospheric pressure (APCVD) by heavily diluting the active gases. When these gaseous precursors are let to react in a rarefied the process is termed Low Pressure CVD (LPCVD). The partial vacuum avoids gas-phase reactions. The low pressure also favors larger diffusivity of the species so that an LPCVD process can decorate cavities and led to conformal coatings when a topography is present. The conformality is also spurred by the process temperature which favors movement of the species along the surface. Pressures are usually in the millitorr-torr range and temperatures range from 400-800C (depending on the energy needed to decompose the gas precursors). PECVD is a particular form of CVD that takes place in vacuum but in which a plasma is used to assist the decomposition of the gas precursors. This usually allows lowering the temperature of the process to a few hundred centigrade degrees, which can be run on less temperature resistant substrates or without setting off temperature triggered unwanted processes.

WARNING: Access to CNRS temporarily not available, but the technique is available at the other sites

PECVD - MicroSys 200 (706)

LPCVD and PECVD @ Laboratory for Micro- and Nanotechnology

CVD and PECVD @ Analytical Laboratory

Sample dimension: 1.2mm x 0.6 mm

Sample holder compatible with several other CNR-IOM laboratories (including STM, IPES, BACH beamline)

The CVD system is directly connected to the following instrumentation, for in situ analysis:

- XPS and UPS analysis chamber, equipped with a conventional X-ray source Mg Ka, He discharge lamp, hemispherical electron energy analyser (120 mm by PSP)

- low energy electron diffraction (LEED)

- supersonic cluster source (AMPHIRO)

- UHV evaporators

- residual gas analyser

- sputter-gun

Semi Engineering LPCVDs

PECVD AMAT P5000 and Oxford Plasmalab800

Reaction chambers under vacuum with plasma RF source (13,56MHz) and LF source (Plasmalab: 50-460KHz) for PECVD process below 400ºC

Precursors: Silane, NH3, N2O, H2, TEOS, TMPi, TMB, O2 and N2

Deposited film thicknesses between 30 nm -3 mm for SiOx, between 30 nm -1.5 mm for SiNx and between 30 nm -300 nm for a-Si

Automatic wafer cassette loading

Plasmalab: manual positioning on the bedplate

All in horizontal position