EBL

Electron Beam Lithography

Lithography & Patterning Installation 1

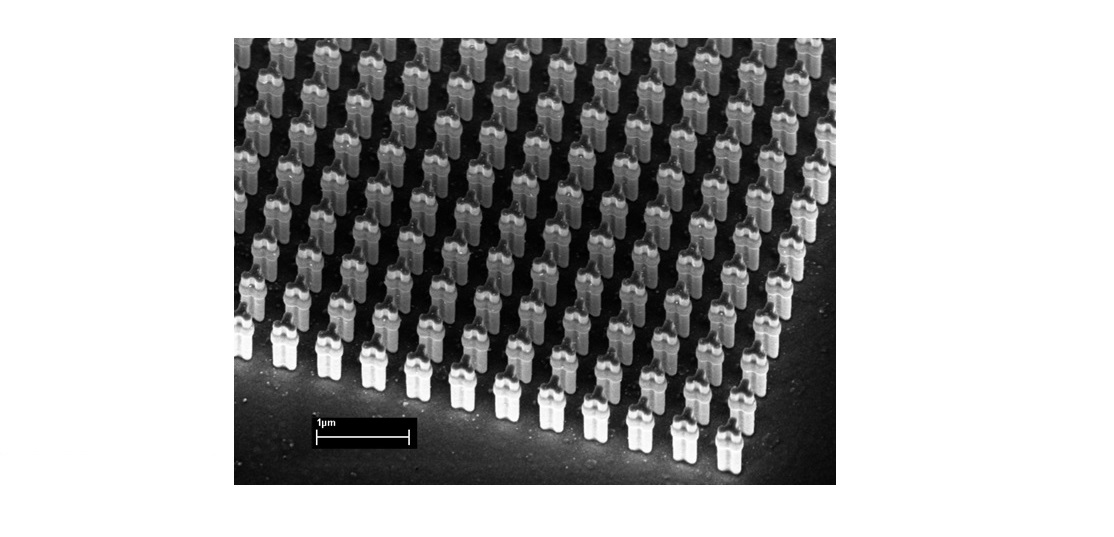

A typical electron beam lithography tool is a vector-scan direct write tool with a Gaussian shaped beam. The electrons are accelerated to typically 50 keV or 100 keV and the beam scanning is controlled by a combination of usually two deflection systems. The beam is directed to a position in the main deflection field (with a maximum size of a few 100 µm²), where a pattern is written by stepping around the electron beam. For larger patterns, the pattern is divided in main field blocks, which are completely exposed one-by-one after moving the substrate to the right position. A laser interferometer can often measure the actual stage position, and this signal is fed back to the deflection system with sub-nm resolutions.

The electron beam stepping frequencies can be as high as 50 MHz, which provides relatively high speed direct nanopatterning. The electron beam spot size can be focused to sub-10 nm in diameter. Owing to the wide range of available beam currents (typically 200 pA – 200 nA), high-throughput as well as high-resolution exposures are possible. With high accelerating voltages, thick layers of e-beam resists can be exposed with small forward electron scattering. Electron-beam lithography systems typically have small overlay precisions and can handle full wafers, mask blanks, and custom shaped samples. Typical features can include automatic laser focusing for height measurement, and manual or automatic detection of alignment markers for multiple lithography level processes. Users can implement or supply their designs in most standard formats.

WARNING: Access to CNRS temporarily not available

EBL - Voyager (44)

EBL - Raith (101)

EBL - Vistec/Raith EBPG 5000+ ES system @ Laboratory for Micro- and Nanotechnology

EBL - LEO-ZEISS Cross-Beam 1540 XB system

EBL - FE-SEM LEO 1530 + Elphy Plus (N6)

EBL - Raith 150 TWO (N2)