Electrochemical deposition

Lithography & Patterning Installation 1

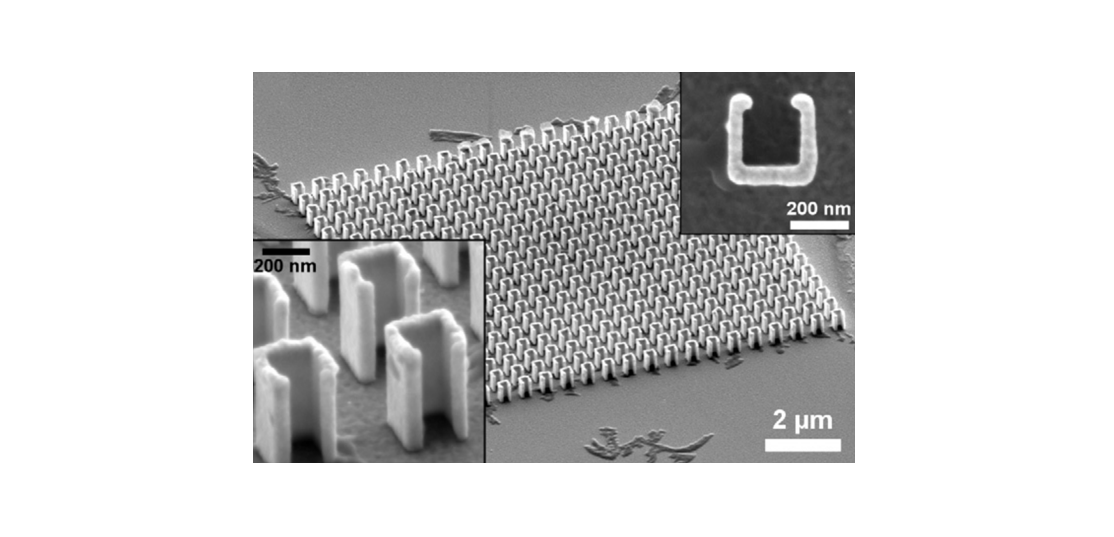

Electrochemical deposition or electroplating is generally used for the deposition of metallic films (Au, Ni) with various advantages. The thickness of the coating can be precisely controlled by adjusting the electrochemical parameters. In addition, compared to standard metal deposition techniques, higher deposition rates can be obtained. The electroplating technique is relatively inexpensive as there are no requirements for high vacuum or high temperature systems. Moreover the resulting coatings are relatively uniform and compact and standard resists can be used as masks during the electroplating process. Last, electroplating is ideal for relatively thick coatings and structures with high aspect ratios.

WARNING: Access to CNRS temporarily not available

Electroplating setups @ Laboratory for Micro and Nanotechnology

Electrochemical deposition

Electroplating Set-up