NIL

NanoImprint Lithography

Lithography & Patterning Installation 1

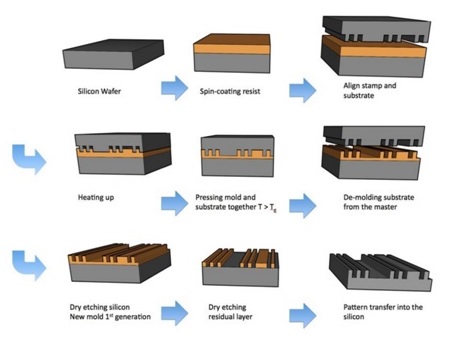

NIL is a novel technique for the fabrication of nanostructures on large surfaces. The method is based on the excellent replication fidelity obtained with polymers. Once a solid stamp with a nanorelief on the surface is fabricated it can be used for the replication of many identical surface patterns. It therefore circumvents many limitations of conventional photolithography. Both thermal NIL into various thermoplastic materials and UV-assisted NIL, e.g. for the fabrication of stamp copies are available with sub-10 nm resolution. Imprint-based solutions can be used for a wide variety of applications and areas such as optics (refractive and diffractive elements, photonics, plasmonics, liquid crystals), biology (templates for cell growth, protein patterning, and crystallization), micro- and nanofluidics (for analysis of transport through lipid bilayers), surface wetting (via modification of hydrophilic and hydrophobic properties) etc.

WARNING: Access to CNRS temporarily not available

NIL 6 inch system - Obducat (306)

Jenoptic HEX 03 hot press @ Laboratory for Micro and Nanotechnology

Automatic lab press

Automatic lab presse Webber PW equipped with an external electro-hydraulic supply station

Automatic lab UV press equipped together with an integrated pneumatic supply station

NIL 4 inch system - Obducat (N4)