RIE

Reactive Ion Etching

Lithography & Patterning Installation 1

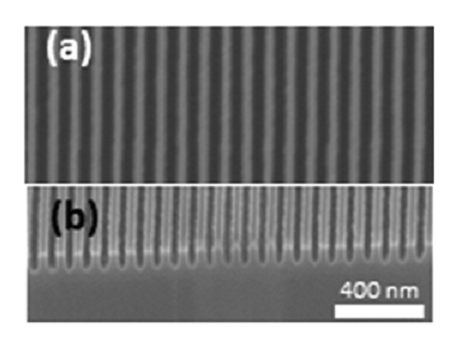

RIE is used to etch various materials under vacuum in the presence of reactive ions. Typically a wide range of materials can be etched by use of various gas mixtures containing fluorine, chlorine, oxygen and other elements. An RF source accelerates stray electrons between a pair of plates in the presence of a low-pressure gas and reactive ions and free radicals (like monoatomic fluorine) are created. The surface to be etched is bombarded by the reactive ions and the material is etched by forming a volatile component. The etching mechanism can either be physical (sputtering mechanism) where the target material is mechanically sputtered away by the accelerated ions, chemical where the ions react with the target material to form a volatile compound, or both. The selection of the etch parameters (gas mixture, gas flow, pressure, RF power and bias) can give control over the anisotropy, selectivity, etching rate, and surface roughness by controlling this etching mechanism.

WARNING: Access to CNRS temporarily not available

Etcher RIE Trion Sirus T2 Plus

Etcher ICP-RIE Plasmalab System 100

Inductively coupled plasma (ICP) reactive ion etching (RIE) for etching almost all different types of materials, including III-V semiconductors, silicon, dielectrics and metals

Only glasses, noble metals (Au, Ag, Pt, Cu, Pd), heavy metals (Cd, Pb, Zn) and silicones are not allowed

Oxford plasmalab Systems 100 @ Laboratory for Micro and Nanotechnology

RIE

MERIE AMAT P5000 Mark II