UVL

Ultra Violet Lithography

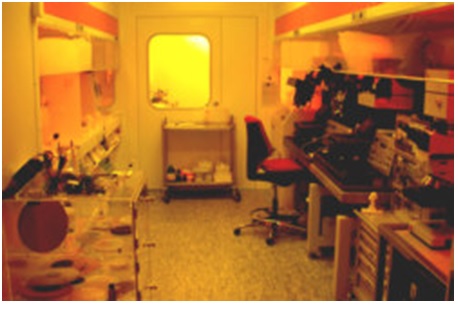

Lithography & Patterning Installation 1

Optical lithography is a fast patterning technique as all patterns are transferred to the photoresist through the mask in parallel. This requires that the relevant photomasks are already available or that they also need to be fabricated usually by electron beam lithography (in the case of non-standard patterns). Standard photomasks are made of fused quartz coated with a layer of chromium. During mask fabrication Cr is etched away where the geometric patterns need to be. This way UV light has a clear path through the mask, so as to expose the photosensitive resist and transfer the patterns, while Cr acts as a light-stop layer to prevent the illumination of the rest of the photoresist. The most common UV light wavelengths used in standard photolithography are the 436 nm ("g-line"), the 405 nm ("h-line") and the 365 nm ("i-line"), all being spectral lines of an Hg lamp. The achievable resolutions at these wavelengths go down to below 1 μm. There are different modes one can perform standard photolithography either with the mask being in contact with the resist-coated sample (contact lithography) or leaving a small gap (proximity lithography) each one having its own advantages and disadvantages.

WARNING: Access to CNRS temporarily not available

Mask aligner MJB4 (soft UV) (316)

Mask Aligners MA6/MA8/MJB3

Mask Aligners MJB3 and MA25

MJB3: high-precision alignment stage accurate to 0.5 µm and a brightfield microscope equipped with 5X, 10X and 25X objectives

MA25: simultaneous double side exposure and manual operation of wafers and small samples, alignment accuracy between upper and lower side of the wafer of <2 microns, and alignment table rotation of <2 degrees

Mask aligner Süss MA6 and MA/BA6