Confocal microscopy

Characterisation Installation 4

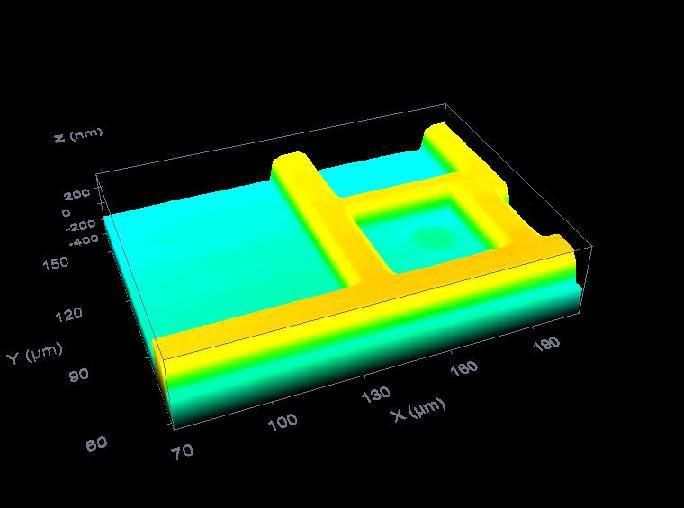

Confocal microscopy is frequently used to determine the surface contours and profiles of micro-structured components and to quantify the height and depth of features; it is also able to build a 3-D image with structure information below the surface.

Confocal microscopy offers several advantages over conventional optical microscopy, including shallow depth of field, elimination of out-of-focus glare, and the ability to collect serial optical sections from thick specimens.

In conventional microscopy, the sample is placed on the microscope stage and the entire field of the specimen is simultaneously illuminated by light and visualized. Although the brightest and highest intensity is at the focal point of the objective lens of the microscope, there is illumination of other parts of the sample, resulting in background “noise,” which compromises the quality of the image. However, in confocal microscopy, a beam of incoming light is focused through the microscope objective on a small spot inside the microstructure. The same objective gathers the reflected or fluorescent light coming back from the sample, but a small pinhole aperture in a screen is used so that only the light emitting from the desired focal spot is allowed to pass through. The screen blocks any light outside of the focal plane (the scattered light). In optical terms, the pinhole is placed in a conjugate focal plane of the sample (hence the designation “confocal”). A sensitive light detector, such as a photomultiplier tube, on the other side of the pinhole is used to detect the confocal light. This technique allows the specimen to be imaged one “point” at a time.

To create virtual-sectioned images of the microstructure, the focal spot is serially scanned in the X–Y plane. As the scanning progresses, signal from the detector is fed to a computer that collects all the “point images” of the sample and serially constructs the image one pixel at a time. Because the sample is not actually sectioned, it is possible to image a “stack” of virtual, confocal images that are displayed on a video monitor and giving place to a high-contrast image that could not be acquired by conventional microscopy.