High precision manufacturing

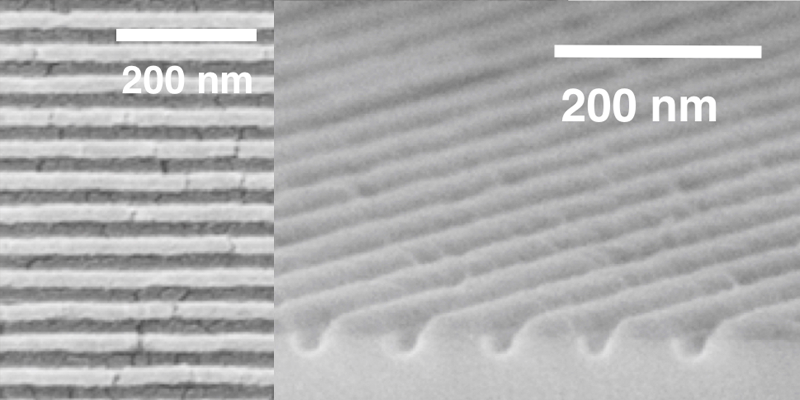

SEM image of 20-nm pattern transfer into SiO2 after nanoimprint and reactive ion etching. This work on investigation of optimal nanoimprint stamp fabrication methods is performed as collaboration between Lund University, PSI, and C2N-CNRS. Credits: Mariusz Graczyk.

JRA2 Research aims to push the limits of high precision nanopatterning by lithography and self-assembly methods. The outcomes of this JRA directly impact on the TA Nanofabrication, but also will enable to build novel advanced instrumentation of use in TA Nanocharacterization.

JRA2 OBJECTIVES

Develop high precision manufacturing by advance of lithography and pattern transfer technologies towards the controlled and reproducible fabrication of sub-10 nm structures in surfaces over an area large enough to perform meaningful scientific experiments.

JRA2 TASKS

T7.1. Novel resist materials and processing & Development of 3D lithography techniques

T7.2. Development of pattern transfer and replication techniques

T7.3. Functionalized nanostructures

JRA2 DELIVERABLES

D7.1. Investigation of optimum NIL stamp fabrication method to copy sub-10 nm BCP features (M18)

D7.2. Protocol for the fabrication of sub-10 nm guiding patterns for DSA of BCPs (M18)

D7.3. Fabrication of sub-10 nm metal structures by line multiplication based on atomic layer deposition (M24)

D7.4. Protocol for the fabrication of aligned patterns of BCPs (M24)

D7.5. Fabrication of nanowire arrays for next generation solar cell applications (M24)

D7.6. Methods for metrology and characterization of BCPs patterns at the sub-10 nm range (M24)

D7.7. Test of 3D hierarchical scaffold with and without liposome membranes (M24)

D7.8. Resolution tests on inorganic resist materials with EBL and EUV lithography (M30)

D7.9. Development of NIL replication using polymer and sol-gel resists (M30)

D7.10. Test of 3D hierarchical scaffolds with embedded protein nanoparticles and natural biomolecules (M30)

D7.11. Test of 2D engineered surfaces (patterns with spatial resolution and gradients) with protein nanoparticles (M30)

D7.12. Investigation of development processes allowing for high ARs (>5) at the 10 nm line width level (M36)

D7.13. Fabrication and synchrotron characterization of 3D nanomagnets arrangement with sub-100 nm resolution (M36)

D7.14. Test of re-alignment of nanostructures in synchrotron experiment by in-situ marker deposition (M36)

D7.15. Realization of coplanar electrode arrays with 10 nm gaps (M36)