MBE

Molecular Beam Epitaxy

Growth & Synthesis Installation 2

Molecular beam epitaxy (MBE) is a growth technique for the deposition of high quality and high purity epitaxial layers on suitable substrates. It is mainly used for the growth of semiconductors, oxides and organic materials.

Fully automated MBE systems for the growth of advanced, compound semiconductor heterostructures, composed of compounds based on III-Arsenide, III-nitride, Si, SiC, Ge, C semiconductor nanostructures with sub-nanometer control of the film thicknesses. The MBE system is used to make nanostructures, including quantum dots and nanowires, and epitaxially layered structures and heterostructures, for the fabrication of lasers, photodetectors, light-emitting diodes and other optoelectronic devices. The MBE systems are equipped with a series of in-situ analytical characterization tools for continuous monitoring of the growth process.

Thermally produced atomic or molecular beams of the constituent materials migrate in Ultra High Vacuum (UHV) environment until impinge on a heated substrate where they are incorporated. The growth rate is generally very slow, of the order of one monolayer (ML) per second, allowing a ML control of the deposition.

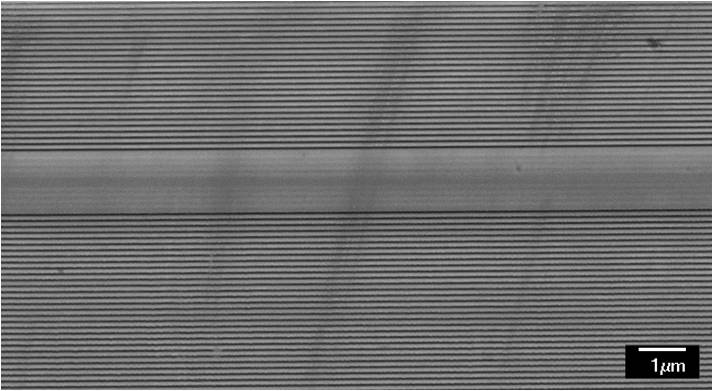

The UHV environment allows for the use of diagnostic techniques during the growth as the reflection high energy electron diffraction (RHEED) and the integration of the growth system with UHV surface characterization techniques. When combined with the referred ability to perform in-situ high-resolution structural and electronic diagnostics of the films as they are being deposited, MBE provides the ideal scenario for understanding many of the fundamental structural and physical properties of ultrathin inorganic and organic film systems.

In some cases, MBE systems should be prepared not only for in-situ characterization but for in operando as well, in order to study the dynamics of growth. This should lead to the design of compact, element or material specific and flexible systems. In operando studies are particularly interesting for understanding catalytic processes.

WARNING: Access to CNRS temporarily not available, but the technique is available at the other sites

III-V and II-VI MBE

For III/V materials: effusion cells for Ga , Al, In, As, Si (n-type dopant), GaTe (n-type dopant) and Be (p-type dopant), RF Plasma source for N; for II/VI materials: effusion cells for Zn, Cd, Se, Te

Oxide MBE

MBE of metal oxide ferromagnetic, antiferromagnetic, superconducting, insulating, ferroelectric, multiferroic ; MBE masked conducting deposition

Sources for Oxide-MBE growth: 3 high temperature effusive cells (up to 1500°C); 3 conventional effusive cells; 2 low temperature effusive cells; ozone/oxygen deposition pressure up to 10-5 mbar; 3d, 4d, 4f metals, organic molecular magnets, MgO, Al2O3, NiO; perovskite structure compounds ABO3: ( La-Sr)(Co-Cu-Ti-Zn)O3, (Ba-K)(Cu-Bi)O3, (Ba-Sr)(Ti-Zr)O3, (La-Ba)(Mn-Fe-Ni-Co)O3, Bi(Fe-Mn)O3; Spinel structure compound AB2O4: ZnFe2O4, Fe3O4

Sources for MBE Masked conducting deposition: Au, Pd, Fe, Co, Mn conductive metals, up to 5 e-bombardment evaporators.

For Oxide-MBE growth: dimensions up to 10x10mm2; T up to 800K

For MBE Masked conducting deposition: dimensions up to 5x5mm2; T range: 35-300K; annealing temperature up to 950K

For Oxide-MBE growth: 2 RHEED guns, electron energy 10 kV, spot size 100 micron diameter; RHEED software analysis KSA-400

For MBE Masked conducting deposition: LEED/Auger spectroscopy OCI BDL800IR; transport measurements Keithley 6487

For MBE Masked conducting deposition. XPS Chamber with: Al and Mg K-alfa X-rays at 1486.7 and 1253.7 eV, electrostatic hemispherical analyzer (radius 200 mm), T range 25-300 K; MOKE magnetometry with: HeNe Thorlabs HNL020L laser 632.8 nm, linear polarization, T range 30-340 K, maximum H-field 0.55 T in UHV, 0.75 T in air, minimum H-field step 0.3 mT, pole face diameter 76 mm, frequency filter HINDS optical chopper 50KHz, Si, Ge photodiode HINDS DET 200-004, spectral range 350-1100 nm

High Mobility MBE

Effusion cells for Ga (2x), Al, In, As, As cracker. Doping: Si (n-type) and C (p-type) direct-heat filament

III/V materials: GaAs/AlGaAs 2D electron gases with low-T electron mobility up to 8X106 cm2/Vs, metamorphic In0.75GaAs/In0.75AlAs quantum wells with low-T electron mobility up to 5X105 cm2/Vs, photonic structures, self-assembled quantum dots on planar and patterned surfaces; dimension up to 2" diameter; T range: up to 700 C; possibility of In-free mounting

III-V MBE 2DEGs and quantum cascade structures

Effusion cells for Ga (2x), Al (2x), In, As cracker. Doping: Si (n-type) and C (p-type) direct-heat filaments

III-V MBE with PL, FTIR and magnetotransport

III-N MBE

III-V MBE microcavities, quantum dots and electro-optical devices

III-V MBE diluted magnetic semiconductors

III-V MBE nanowires

SiGe MBE

III-As MBE

Group IV elements MBE

III-Nitrides MBE

Thin film MBE

4 high temperature effusive cells (up to 1800°C); 2 low temperature effusive cells (up to 1400°C); plasma source for oxygen/nitrogen (plasma up to 600W) with deposition pressure up to 10-5mbar; 2 e-guns with 4 crucibles; typical evaporation materials: Fe, Co, Au, Ag, Ni, Sr, Ti, Mn, Nb, Pt, Cu, Cr, other materials on request.

RHEED gun, electron energy 20 kV, RHEED software analysis KSA-400; LEED up to 1 kV; AES up to 5 kV; residual gas analyzer; quartz micro balance

Script based programming of sample preparation/growth

A new offer is a special transfer chamber allowing the transfer and measurement of thin films under UHV conditions. After growth of the thin film samples with the MBE setup, they can be transferred into the transfer chamber without breaking the vacuum. The samples can be measured with MNR (Installation 6, Characterisation) at a pressure better than 10-9 mbar at room temperature and in magnetic fields up to 300 mT.