SEM

Scanning Electron Microscopy

Characterisation Installation 4

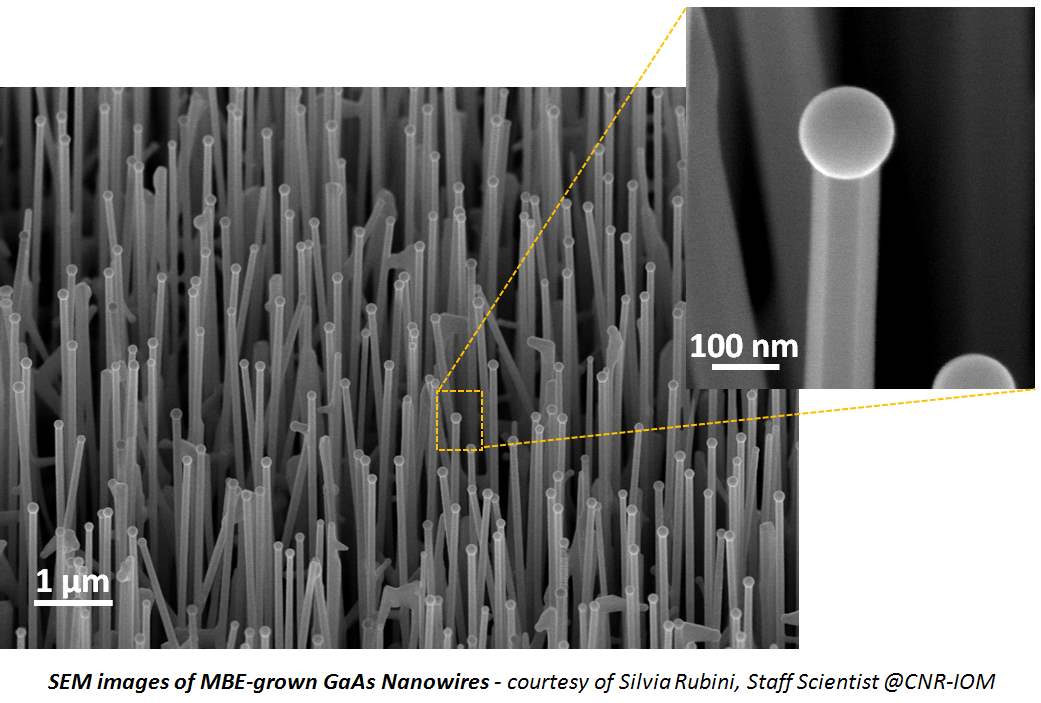

In a SEM, a beam is scanned over the sample surface in a raster pattern while a signal from secondary electrons (SE) or Back-scattered electrons (BSE) is recorded by specific electron detectors. The electron beam, which typically has an energy ranging from a few hundred eV up to 40 keV, is focused to a spot of about 0.4 nm to 5 nm in diameter. Latest generation SEMs indeed can achieve a resolution of 0.4 nm at 30 kV and 0.9 nm at 1 kV.

Beyond the ability to image a comparatively large area of the specimen, SEM can be equipped with a variety of analytical techniques for measuring the composition, crystallographic phase distribution and local texture of the specimen. Chemical composition analysis can be performed by Energy Dispersive X-ray Spectroscopy (EDS) which relies on the generation of an X-ray spectrum from the entire scan area of the SEM. An EDS detector mounted in the SEM chamber collects and separates the characteristic X-rays of different elements into an energy spectrum and EDS system software is used to analyse the energy spectrum in order to determine the abundance of specific elements. EDS can be used to find the chemical composition of materials down to a spot size of a few microns and to create element composition maps over a much broader raster area.

An SEM complemented with a (FIB) focused ion beam permits in addition an in-depth analysis by creating a cross-section cut that is subsequently analysed using the electron beam and the SEM/EDS detectors (slice&view). In a similar way, a 3D tomography can be generated by an iterative ion beam milling and electron beam imaging. Furthermore, the ion beam permits to cut a thin lamella out of a sample surface that could be taken out by a micro-manipulator and analysed with the electron beam in transmission using a so called STEM (scanning transmission electron microscope) detector.

WARNING: Access to CNRS temporarily not available, but the technique is available at the other sites

SEM – FEI Quanta 650 FEG ESEM

SEM – FEI Magellan 400L XHRSEM

SEM - LEO 1560

Hitachi SU8010

JEOL JSM-6700F SEM

SEM – Zeiss Merlin

Zeiss Supra 55 VP @ Laboratory for Micro- and Nanotechnology

Hitachi H5500 High resolution SEM

SEM @ DESY NanoLab

Imaging of surfaces in reflection mode, in scanning mode and scanning transmission microscopy (STEM), elemental analysis by EDX (point and line analysis, mappings)

SE Everhart-Thornley detector (ETD)

Low vacuum BE detector

High resolution through-lens detector tunable for SE and BE mode

High resolution STEM detector for analysis of membranes and thin films in transmission

X-Max 150 EDS silicon drift detector for elemental analysis, energy resolution 127 eV @ MnKα (Oxford)

IR-CCD camera to track the sample position

SEM-EDX

High efficiency in-lens detector

Everhart-Thornley Secondary Electron Detector

Cap mounted AsB detector

CCD-camera with IR illumination

FIB-SEM

FE-SEM LEO 1530 + Elphy Plus (N6)

QUANTA FEI 200 FEG-ESEM

Imaging, size, morphology and microstructure; high-profile nanostructural characterization; non-destructive analytical techniques (imaging and microanalysis); nanometer level inspection of materials, lithography and nanolithography

EDT - Detector Everhart Thornley: high-vacuum mode, EDX mode, RAITH mode

BSED - Solid State Backscatter Detector: high-vacuum mode, low-vacuum mode, EDX mode, RAITH mode

CCD - Infrared inspection camera: high-vacuum mode, low-vacuum mode, Environmental mode, RAITH mode

LFD - Large Field detector: low-vacuum mode, EDX mode

GSED - Gaseous Detector: Environmental mode

High-vacuum: 1.2nm at 30kV (SE), 2.5nm at 30kV (BSE), 3.0nm at 1kV (SE)

Low-vacuum: 1.5nm at 30kV (SE), 2.5nm at 30kV (BSE), 3.0nm at 3kV (SE)

Environmental mode: 1.5nm at 30kV (SE)

EDX mode: energy resolution of 132 eV, chemical analysis with a high lateral resolution (point analyses and elemental mapping)

Conducting materials (High-vacuum)

Uncoated non-conducting materials (Low-vacuum, Environmental mode)

Complex multi-component nanostructured materials (EDX)